Cannabis Drying and Curing: How to Preserve Terpenes, Smoothness, and Potency

“The curing process can make the difference between decent and decadent weed. Free of excess moisture that renders plants more susceptible to spoilage and disease, properly dried and cured buds offer a stronger aroma, better taste, and more potency.”

Drying and curing are the most overlooked stages of cannabis production—and the ones that most directly determine final quality. Aroma, flavor, smoothness, and long-term potency are all shaped after harvest. Even exceptional genetics and meticulous cultivation can be compromised if post-harvest conditions are rushed or unstable.

Drying and curing are not passive waiting periods. They are controlled physical and biochemical processes. When handled correctly, they preserve what the plant has already produced. When handled poorly, they permanently diminish it.

Drying and curing at home can be a challenge for many growers. Even when a basement can double as a drying space, maintaining consistent temperature and humidity is often difficult without dedicated environmental control.

Why Drying and Curing Matter More Than Most Growers Think

Many indoor and tent growers simply do not have access to dedicated drying rooms. Flowers are often hung in closets, garages, spare bathrooms, or under roofs and attics where temperature and humidity fluctuate dramatically.

A common mistake is drying too fast. Warm air and low humidity pull moisture from the outside of the flower before internal moisture can redistribute. This leads to harsh smoke, flattened aroma, and uneven curing. Once that damage is done, it cannot be reversed.

This is why experienced growers emphasize a “low and slow” approach. Cooler temperatures and moderate humidity allow moisture to leave the flower gradually and evenly, protecting terpenes and improving smoke quality.

The Science Behind “Low and Slow” Drying

For our first VCure test batch, we used the Grand Caper variety from Purple Caper Seeds. This macro image captures trichome development at harvest, before drying and curing began. Photo Credit Ginja.Club

Moisture Migration and Case Hardening

Fresh cannabis flowers contain significant internal moisture. During drying, water migrates from the interior of the bud toward the surface and then into the surrounding air.

If the surrounding air is too warm or too dry, surface moisture evaporates faster than internal moisture can move outward. This creates a steep moisture gradient—often referred to as case hardening. The outside of the flower may feel dry, while the inside remains wetter than it should be.

This uneven state leads to:

Harsh smoke

Inconsistent curing

Increased mold risk in dense flowers

Slower drying minimizes this gradient by giving internal moisture time to equalize.

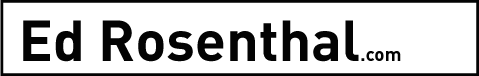

Slower drying preserves volatile terpenes, while fast drying accelerates aromatic loss. This is why low temperatures and extended drying times consistently produce better results.

Temperature, Terpenes, and Volatility

Terpenes are volatile aromatic compounds. Many evaporate or degrade rapidly at elevated temperatures. Fast, warm drying drives off lighter terpenes first, reducing aroma complexity and dulling cultivar-specific character.

Drying at 60–65°F (15–18°C) significantly improves terpene retention compared to warmer environments.

What Happens During Cannabis Curing

Curing is a stabilization and refinement phase that begins after the initial dry.

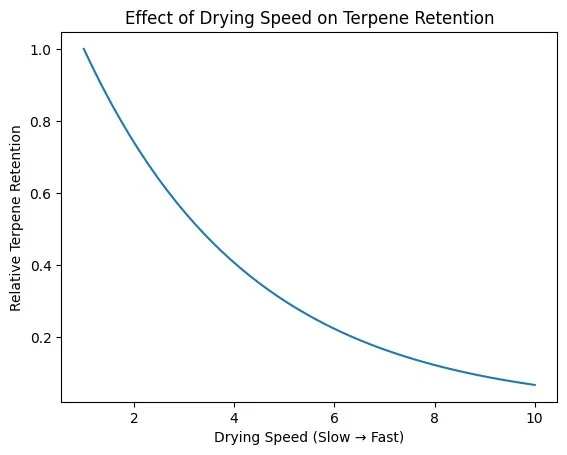

Curing humidity involves balancing microbial risk against overdrying and terpene loss. Around 60% relative humidity represents a practical compromise for most cultivars.

Moisture Equalization and Burn Quality

Even well-dried flowers still contain unevenly distributed moisture. Curing allows remaining moisture to redistribute evenly throughout the bud, improving texture and burn consistency.

This results in:

Smoother smoke

More even combustion or vaporization

Better grind and handling

Chlorophyll Breakdown and Smoothness

The harsh “green” taste associated with poorly cured cannabis comes from chlorophyll-related compounds and other plant metabolites. During curing, these compounds continue to break down slowly, allowing terpene expression to come forward and harshness to diminish.

Cannabinoid Stability

Cannabinoids degrade over time, especially when exposed to heat and fluctuating humidity. Stable curing conditions reduce unnecessary oxidation and help preserve potency over longer storage periods.

Why 60°F (15°C) / 60% RH Became the Reference Point

The commonly cited curing target of 60°F (15°C) and 60% relative humidity reflects a practical balance:

Low enough humidity to reduce microbial risk

Cool enough temperatures to slow terpene loss

Stable conditions for long-term storage

While no single setting is perfect for every cultivar, 60/60 remains a reliable baseline for consistent results.

Why Home and Tent Growers Struggle With Post-Harvest Control

Even growers who understand ideal conditions often struggle to maintain them. Common challenges include:

HVAC cycling that causes humidity swings

Outdoor weather influencing indoor RH

Inadequate airflow control

Heat buildup in upper floors or attics

The result is inconsistency from harvest to harvest—even when cultivation practices remain unchanged.

A Controlled Approach to Drying, Curing, and Storage

This is where purpose-built post-harvest systems become valuable. The VIVOSUN VCure Smart Post-Harvest Box is designed to provide stable, repeatable control over drying, curing, and holding within a single enclosed system by actively regulating temperature and relative humidity.

The VCure is rated to hold up to approximately 2.5 pounds of wet plant material, making it suitable for small to mid-scale home harvests. Capacity is optimized through proper preparation. Wet trimming buds and removing excess stems and leaf material prior to loading reduces bulk, improves airflow uniformity, and allows the internal volume to be used more efficiently.

With this preparation, the VCure can roughly accommodate the yield from a full 4×4 tent harvest when processed as flower-only material, with capacity varying based on cultivar structure and trimming approach. Uniform airflow across trimmed buds supports consistent moisture reduction, while integrating drying, curing, and holding into a single controlled environment reduces handling steps and limits exposure to ambient conditions.

Loading the VCure trays with Grand Purple from Purple Caper Seeds and Ed Rosenthal Super OG from our most recent run. For efficiency, the buds are roughly wet-trimmed and dried and cured as individual flowers to maximize usable tray space.

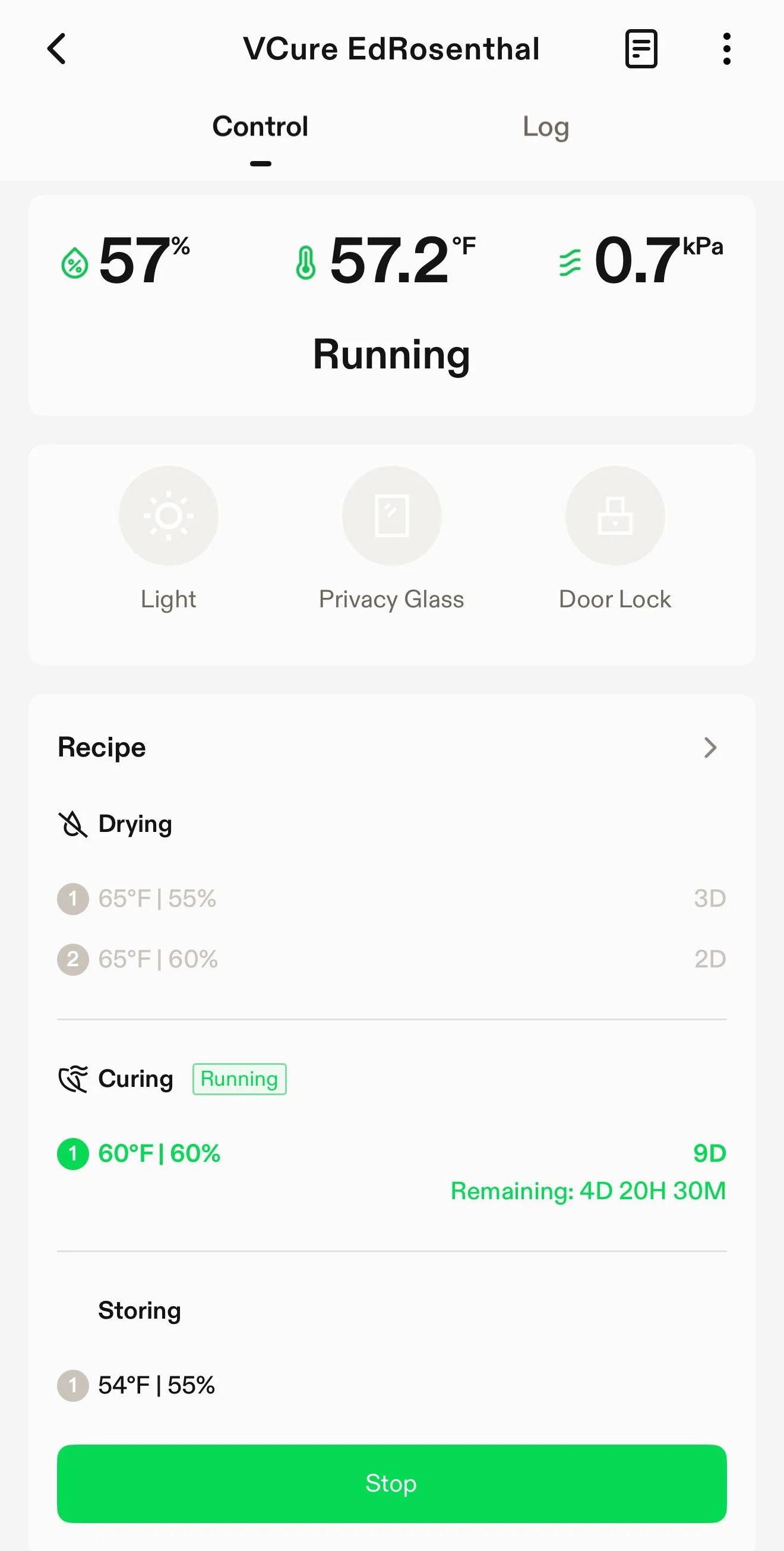

Dialing in a Repeatable Drying and Curing Recipe

The VCure allows growers to create multi-stage drying and curing cycles using either a smartphone app or the integrated touchscreen on the front door. This enables precise control over temperature and relative humidity across each phase of post-harvest processing. The system includes two preset recipes as a starting point, while also allowing straightforward customization based on individual experience, cultivar characteristics, and desired outcomes. Settings and results can be documented easily, supporting record keeping and controlled experimentation across successive harvests.

For the initial trial run, we discussed our post-harvest approach directly with Purple Caper Seeds and elected to run their recommended drying and curing framework. The schedule below reflects that first recipe, which is intended to support gradual moisture reduction and stabilization:

Stage 1 – Drying:

3 days at 65°F (18°C) and 55% RHStage 2 – Drying Transition:

2 days at 65°F (18°C) and 60% RHStage 3 – Curing:

9 days at 60°F (15°C) and 60% RH

This stepped configuration is designed to limit moisture gradients within the flower, reduce the likelihood of surface overdrying, and promote more uniform internal moisture distribution.

For subsequent cycles, the drying temperature may be reduced to 60°F (15°C) during the initial drying stages. In addition, extending both Stage 1 and Stage 2 by one day is under consideration in order to further moderate the rate of moisture loss. The ability to record and repeat specific environmental profiles makes it possible to evaluate these adjustments systematically and compare their effects on terpene retention and overall flower stability across multiple runs.

Holding Mode: Long-Term Preservation

An important additional function of the VCure is its holding mode, which is particularly useful between grow cycles or when flower is intended for longer-term storage. Once curing is complete, the unit maintains stable temperature and humidity, functioning similarly to a cigar humidor.

This sustained environmental stability helps conserve:

Terpene content

Cannabinoid potency

Overall flower integrity

By minimizing temperature and humidity fluctuations, holding mode supports continued preservation of finished cannabis beyond the initial cure period.

Quiet, Discreet, and Design-Conscious

In addition to performance, practical considerations matter for home growers. The VCure operates quietly enough for living spaces and features a clean, modern design. Rather than being hidden away, it can sit comfortably in a living room as a functional showpiece.

Key Takeaways: Drying and Curing Cannabis

Drying and curing are active scientific processes, not passive waiting

Fast drying leads to terpene loss, harsh smoke, and uneven moisture

“Low and slow” preserves aroma, smoothness, and cultivar character

Curing stabilizes moisture and reduces green plant compounds

Consistency matters more than speed

Controlled environments deliver repeatable, high-quality results

Final Perspective

Drying and curing are not optional finishing steps—they are the final, decisive stages of cannabis production. When rushed or left in unstable environments, they can undo months of careful work.

For home and tent growers without access to dedicated climate-controlled rooms, controlled post-harvest systems offer a practical solution. By stabilizing temperature and humidity, enabling repeatable multi-stage cycles, and supporting long-term storage, the VIVOSUN VCure addresses one of the most common quality bottlenecks in small-scale cannabis cultivation: the final step that makes good cannabis great.

For growers looking to bring greater consistency to drying, curing, and storage, controlled post-harvest systems are becoming a viable option—particularly where dedicated climate-controlled rooms are not available. In our testing, the VIVOSUN VCure proved to be a well-designed tool for managing these stages in a repeatable and controlled way.

The initial crowdfunding release sold through its first 999 units quickly, and general shipping is expected to begin in February. Readers who wish to learn more can do so directly through VIVOSUN; a 15% discount is available using code ED420.